Browse our collection of fan arrays and fan sections:

Mainstream stands as a leading manufacturer of Fan Arrays, relentlessly innovating in the realm of Permanent Magnet Synchronous Reluctance Motor (PMEC) technology and array configurations.

Understanding the complex needs of stakeholders during air handling unit replacement and retrofit projects, we aim to exceed their expectations. Our streamlined sales process, reliable products, and commitment to easing engineers’ maintenance duties highlight our client-first approach.

We’re deeply invested in energy efficiency. Our advanced PMEC-powered fan arrays, also known as fan walls, are designed to maximize performance while reducing energy consumption, generating considerable energy bill savings for building managers and owners.

At Mainstream, we aim to create lasting relationships with our clients, offering unrivaled support and services that consistently surpass expectations. We believe in contributing towards a more energy-efficient and sustainable future.

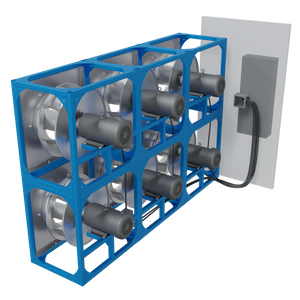

The IntelliCUBE design was developed to handle larger fans, greater flows, and higher pressures. Manufactured with a welded, structural steel frame, IntelliCUBE is designed to be stacked 6 or more fans high. The cubes are powder-coated for protection. The cubes are designed to be stacked in the field and simply bolted together at the corners. The array ships factory-tested with a power distribution panel for single-point power and control.

Great for:

- Large, high static pressure applications

- Where larger fans are the most efficient selection

Max CFM: 300,000 +

Max Static Pressure: 14”

Max Motor Size: 20 HP

Motor Technology: PMEC, AC

Options Available: N+1 Redundancy, Premium Controls, Backdraft Dampers, Pre-wired whips, acoustically insulated cubes

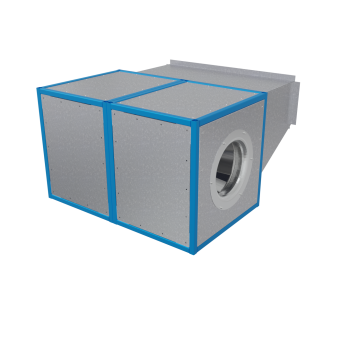

Mainstream’s double-width, double-inlet fan array was designed specifically for replacing DWDI housed fans. With a familiar cube design, the cubes are enclosed and secured back-to-back, with an open side to be transitioned to the existing supply duct discharge. The array ships factory-tested with a power distribution panel for single-point power and control.

Great for:

- Applications where open plenum fans will not work. For example, where a housed fan is butted up too close against a coil, and the inlet of a plenum fan would be unacceptably close. The DWDI design keeps the inlets of the fans perpendicular to the airflow.

- Applications where keeping the fan section under negative pressure is important. For example, in an old unit where the cabinet is not in suitable shape to handle positive pressure.

Max CFM: 40,000 CFM

Max Static Pressure: 12”

Max Motor Size: 15 HP

Motor Technology: EC, PMEC, AC

Options Available: N+1 Redundancy, Premium Controls, Backdraft Dampers, Pre-wired whips

Mainstream’s bulkhead design is a great solution for retrofitting smaller air handling units. The array is supplied with galvanized steel panels that bolt together to form the bulkhead, and the fans ship loose to be bolted on to the bulkhead in the field. The array ships factory-tested with a power distribution panel for single-point power and control.

Great for:

- Smaller applications (1 – 3 fans)

- Where access is extremely limited

Max CFM: 100,000 +

Max Static Pressure: 8”

Max Motor Size: 7.5 HP

Motor Technology: EC, PMEC

Options Available: N+1 Redundancy, Premium Controls, Backdraft Dampers, Pre-wired whips

Air Handling Unit Fan Sections

When it comes to the design and manufacture of commercial fan sections, Mainstream is the expert. Mainstream’s flexible and innovative designs are sure to suit any of your needs, whether it’s expedited lead times or unconventional design. We offer the MLR Series and MLRa Series of commercial fan sections units.

Benefits of MLR & MLRa Series:

- Full access for servicing components

- Minimal disruption to existing ductwork and piping, thanks to the ability to match an existing footprint

- Ease of installation; sections can be made small enough to fit through doorways, etc.

- Minimal infiltration, exfiltration and radiant heat conduction mean impressive energy savings